STEEL CORD CONVEYOR BELTS

Contact Us

1.Application

Steel cord conveyor belts are widely used in high strength, long distance and heavy load transportation of materials, and they are also used in high strength and short distance transportation of materials on special occasions.

2.Classification

Steel cord conveyor belts include belts of ordinary, oil-resistant, heat-resistant, acid-alkali-resistant, cold-resistant, flame-retardant, tear-resistant, lifting and so on.

3.Features

●High tensile strength: The belts are suitable for large span, long distance transportation of materials.

●Small elongation in use:The belts need only a very short take-up stroke distance.

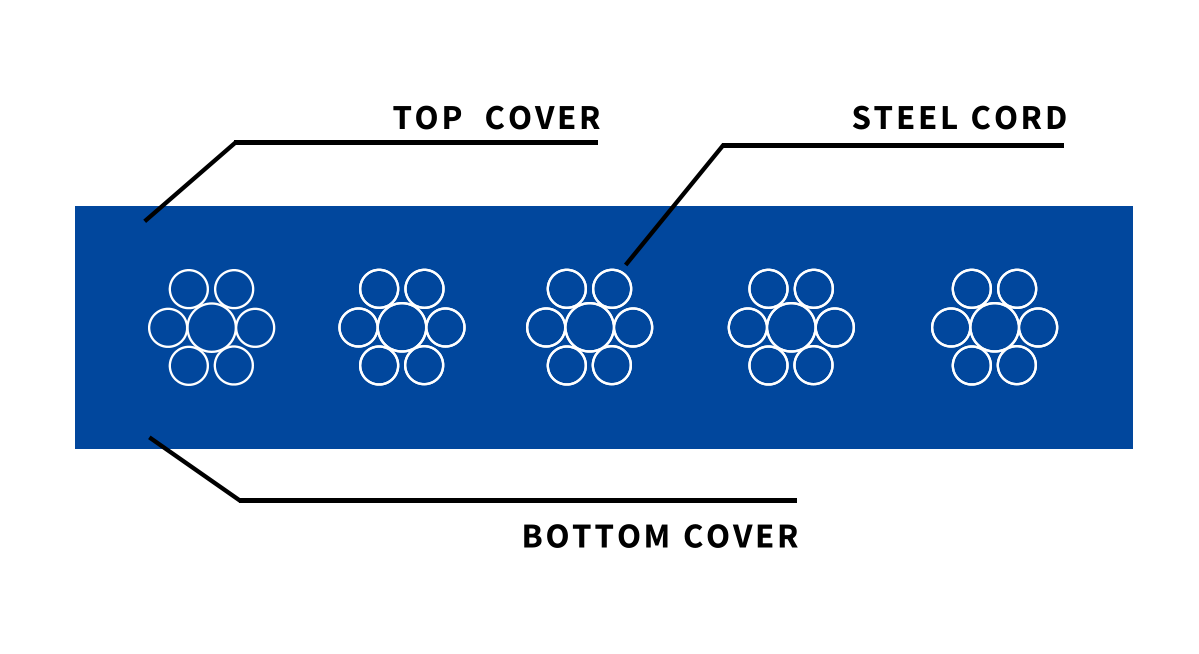

●Small diameter of drive pulley: The belt body has a layer of longitudinally arranged steel cords as its skeleton, and thus is resistant to flex fatigue. Therefore, drive pulley of smaller diameter can be used to make the equipment smaller.

●High adhesion between rubber and steel cord:The steel cords are coated with zinc on their surface, and also the rubber used has the property of good adhesion with steel cords. Therefore, the rubber is tightly adhered to the steel cords and is resistant to shock and difficult to drop, so the rubber belts are long in life.

●Even tension of steel cords: Out of our advanced techniques in manufacturing, the steel cords are very evenly arranged and have the same tension, so the belts are well balanced in running and difficult to run away.

●Good troughability: As the belt body has no transverse skeleton, it is easy to form a deep trough, so the belts can load more materials and prevent the materials from escaping.

●Inspection of the belt with X-rays: Users can use X-rays to inspect damages of the skeleton steel cords on the conveyor machines to prevent accidents from happening.

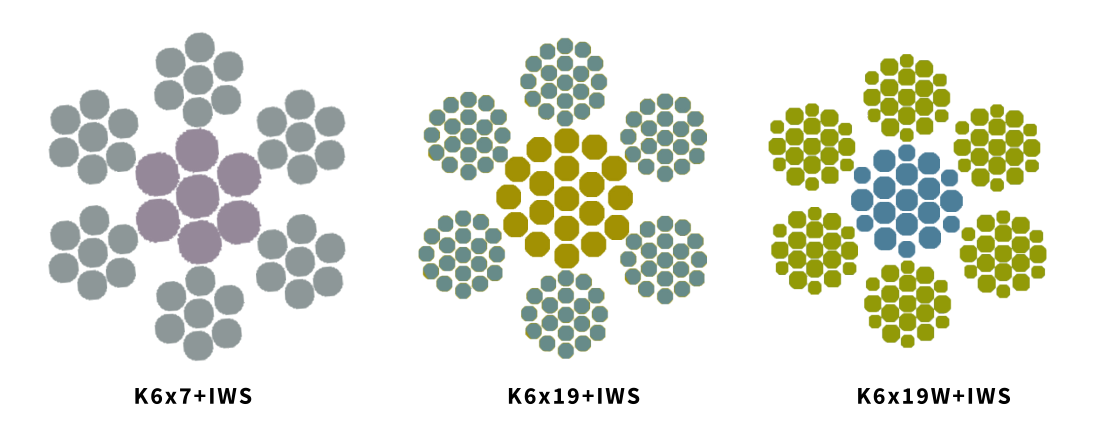

4.Steel cord construction

5.Belt types

| Type | 500 | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 | 7000 | 7500 | |

| Tensile Strength KNmin(N/mm) |

500 | 630 | 800 | 1000 | 1250 | 1600 | 1600 | 1800 | 2000 | 2250 | 2500 | 2800 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 | 7000 | 7500 | |

| Max Cord Diam. dmax (mm) |

3.0 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | 5.0 | 5.6 | 6.0 | 5.6 | 7.2 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 12.8 | 13.5 | 15.0 | |

| Min Breaking Force Fbsmin(kn) |

7.6 | 7.0 | 8.9 | 12.9 | 16.1 | 20.6 | 20.6 | 25.5 | 25.6 | 26.2 | 40.0 | 39.6 | 50.5 | 56.0 | 63.5 | 76.3 | 91.0 | 98.2 | 130.4 | 142.4 | 166.7 | |

| Cord Pitch t(mm) |

14.0 | 10.0 | 10.0 | 12.0 | 12.0 | 14.0 | 12.0 | 13.5 | 12.0 | 11.0 | 15.0 | 13.5 | 15.0 | 15.0 | 15.0 | 16.0 | 17.0 | 17.0 | 19.5 | 19.5 | 21.0 | |

| Min.Cover Thicknes smin(mm) |

4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 5.0 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 | 10.0 | 10.0 | 10.0 | |

| Belt width B(mm) |

Limit deviation (mm) |

No.of cords | ||||||||||||||||||||

| 500 | +10/-5 | 33 | 45 | 45 | 39 | 39 | 34 | 39 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A | N/A |

| 650 | +10/-7 | 44 | 60 | 60 | 51 | 51 | 45 | 51 | 46 | 52 | 56 | 41 | 46 | 41 | 41 | 41 | 39 | 36 | N/A | N/A | N/A | N/A |

| 800 | +10/-8 | 54 | 75 | 75 | 63 | 63 | 55 | 63 | 57 | 63 | 69 | 50 | 57 | 50 | 50 | 50 | 48 | 45 | 45 | N/A | N/A | N/A |

| 1000 | ±10 | 68 | 95 | 95 | 79 | 79 | 68 | 79 | 71 | 79 | 86 | 64 | 71 | 64 | 64 | 64 | 59 | 55 | 55 | N/A | N/A | N/A |

| 1200 | ±10 | 83 | 113 | 113 | 94 | 94 | 82 | 94 | 85 | 94 | 104 | 76 | 85 | 76 | 77 | 77 | 71 | 66 | 66 | 58 | 59 | 54 |

| 1400 | ±12 | 96 | 133 | 133 | 111 | 111 | 97 | 111 | 100 | 111 | 122 | 89 | 99 | 89 | 90 | 90 | 84 | 78 | 78 | 68 | 69 | 64 |

| 1600 | ±12 | 111 | 151 | 151 | 126 | 126 | 111 | 126 | 114 | 126 | 140 | 101 | 114 | 101 | 104 | 104 | 96 | 90 | 90 | 78 | 80 | 73 |

| 1800 | ±14 | 125 | 171 | 171 | 143 | 143 | 125 | 143 | 129 | 143 | 159 | 114 | 128 | 114 | 117 | 117 | 109 | 102 | 102 | 89 | 90 | 83 |

| 2000 | ±14 | 139 | 191 | 191 | 159 | 159 | 139 | 159 | 144 | 159 | 177 | 128 | 143 | 128 | 130 | 130 | 121 | 113 | 113 | 99 | 100 | 92 |

| 2200 | ±15 | 153 | 211 | 211 | 176 | 176 | 154 | 176 | 159 | 176 | 195 | 141 | 158 | 141 | 144 | 144 | 134 | 125 | 125 | 109 | 110 | 102 |

| 2400 | ±15 | 167 | 231 | 231 | 193 | 193 | 168 | 193 | 174 | 193 | 213 | 155 | 173 | 155 | 157 | 157 | 146 | 137 | 137 | 119 | 119 | 110 |

| 2600 | ±15 | 181 | 251 | 251 | 209 | 209 | 182 | 209 | 189 | 209 | 231 | 168 | 188 | 168 | 170 | 170 | 159 | 149 | 149 | 129 | 129 | 120 |

| 2800 | ±15 | 196 | 271 | 271 | 226 | 226 | 197 | 226 | 203 | 226 | 249 | 181 | 202 | 181 | 183 | 183 | 171 | 161 | 161 | 139 | 139 | 129 |

| 3000 | ±15 | 210 | 291 | 291 | 243 | 243 | 211 | 243 | 218 | 243 | 268 | 195 | 217 | 195 | 195 | 195 | 183 | 172 | 172 | 149 | 149 | 139 |

| 3200 | ±15 | 224 | 311 | 311 | 260 | 260 | 225 | 260 | 233 | 260 | 286 | 208 | 232 | 208 | 208 | 208 | 196 | 184 | 184 | 160 | 160 | 149 |

Note:N/A is not available due to troughability.

6.Cover grades

| Test item | Property index | ||||||

| GB/T 9770-2013 | HG/T 3973-2007 | ||||||

| H | D | L | H | D | L | ||

| Tensile strength | Mpa≥ | 24 | 18 | 15 | 20 | 18 | 15 |

| Elongation at break | %≥ | 450 | 400 | 350 | 400 | 400 | 350 |

| After aging (70℃,7d) Change rate of tensile strength Change rate of elongation at break |

% | -25-+25 | -25-+25 | -25-+25 | -25-+25 | -25-+25 | -25-+25 |

| Abrasion | mm³≤ | 120 | 100 | 200 | 200 | 120 | 200 |

Related Products

ABRASION RESISTANT ENERGY SAVING CONVEYOR BELTS

This belt is especially suitable for medium, long-distance transportation of materials, used in lines of mining,ports, electricity, metallurgical industry, chemical industry, coal mines and etc.

IMPACT RESISTANT CONVEYOR BELTS

This belt can bear the impact of sharp and large particle size ores, especially for the primary and secondary crushers in mines and great drop height operation conditions.

SUPER ABRASION RESISTANT CONVEYOR BELTS

Super Abrasion Resistant Belts are especially suited for medium to long length transportation in mines,ports, electric power,metallurgy, chemical, coals and other industries.

It is suitable for medium and short distance material transportation, and widely used in mine, metallurgical,construction, port and other industries.

STEEL CORD CONVEYOR BELTS

High-intensity

long-distance

high-traffic occasions

Contact Us